Made In India! Pune based start-up firm develops 3D-printed masks with antiviral properties

Total Views |

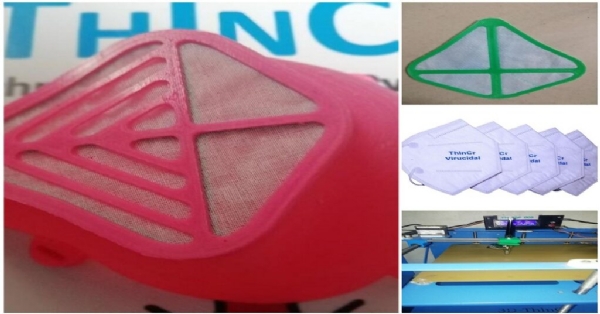

Pune, June 14: In the major development, a Pune-based start-up company developed 3D-printed Masks coated with anti-viral agents that kill viruses when they come in contact with them inside the mask. These cost-effective masks are more effective in containing the spread of COVID-19 as compared to ordinary N-95, 3-ply, and cloth masks. The mask is developed by the Thicr technologies India, and these masks are coated with anti-viral agents known otherwise as virucides.

The viricidal mask project was one the earliest projects supported by the Technology Development Board (TDB) for commercialization soon after the pandemic hit the country last year, a department of the science said on Monday.

The firm developed the masks with support from Merck Life Sciences. Coating formulation has been utilized to coat fabric layers and 3D printing principle was employed to bring uniformity of coating. This coated layer can be incorporated as an additional layer in other masks. Masks comprise reusable filters, developed using 3D printing.

The coating formulation was subsequently used to coat the fabric layer and the 3D printing principle was employed to achieve uniformity of coating. The coated layer can be incorporated as an additional layer in N-95 masks, 3-Ply masks, simple cloth masks, 3D printed or other plastic cover masks, along reusable filters. These masks thus provide additional protection beyond the protection achieved by filtration mechanisms.

The coating is seen to inactivate the SARS-COV-2 virus. The material used for coating on the mask is a solution based on sodium olefin sulphonate. It is a soap forming agent with hydrophilic and hydrophobic properties. In contact with enveloped viruses, it disrupts the outer membrane of the virus. The ingredients used are found to be stable at room temperature and are widely used in cosmetics.

Giving the information, ThinCr Founder Director Shitalkumar Zambad, said that “We started thinking of the problem and possible solutions, during the initial days of the pandemic. We sensed that use of face masks will become nearly universal as the most important tool to prevent infection. But we realized that most masks that were then available and within the reach of common people were homemade and of relatively low quality. It is this need for high-quality masks that led us to undertake a project.”

.

.